97% customer satisfaction based on last 45 days of sales

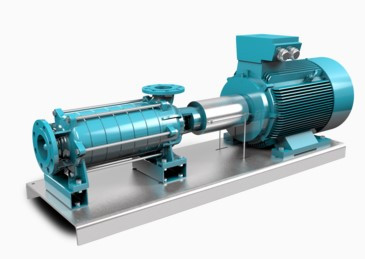

Edur LUB Series Single Stage Inline Pumps

Brand:

Product Code:

LUB Series

Order Processing & Delivery Information:

As we supply industrial equipment, product availability and delivery timelines may vary. Once your order is placed, our sales team will contact you within 24 business hours (excluding weekends and holidays) to confirm stock status and estimated delivery time.

Product Documentation/Technical Datasheet

Tags and Keywords:

🎯 Need a Quote for Edur LUB Series Single Stage Inline Pumps?

Get the best price and fastest delivery for Edur LUB Series Single Stage Inline Pumps from Edur. Imtek Engineering offers worldwide industrial equipment supply with expert support.