Fields of Application and Conveyed

Fluids

Depending on customer requirements, our single stage close-coupled pumps

are used in many applications: They can be used for cooling technology, energy

technology, industrial cleaning technology, water and wastewater technology as

well as in the chemical industry. The pumps are particularly suitable for the

supply of pure or slightly contaminated liquids.

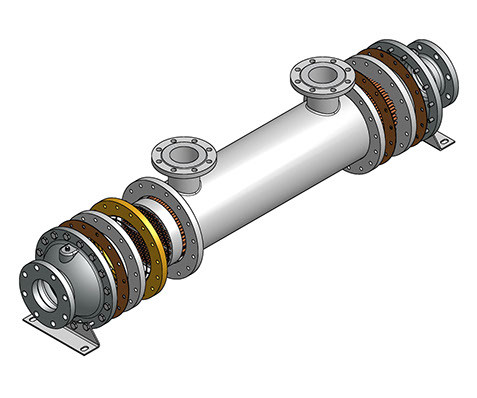

Variants of the Single

Stage EDUR-Close-Coupled Pump

EDUR offers high-quality

single stage close-coupled pumps with our NUB,

CB and BC series. The pumps are available in a variety of

construction styles and materials (e.g. grey cast iron,

spheroidal graphite iron, bronze or stainless steel) as well as with various

shaft seal systems and drive

solutions. We deliver customer-specific configurations matched to our

customer's requirements. Of course, we also provide certificates of all

authorized classification societies and necessary test reports.

Advantages

EDUR-single stage

close-coupled pumps stand out due to their efficient,

economic, reliable, and long-lasting performance.

Additional product advantages as well as technical characteristics are outlined

below:

Axial

thrust-free, open or load-relieved, closed impellers

Compensation

of radial forces due to diffuser elements in the ring housing

Low

NPSH values

Possibility

to convey gas-loaded liquids

Excellent

control behavior

Robustness

against certain amounts of solid contents

Optimized

size of pressure nozzle for low pipe friction losses and velocity head

difference

Protection

against dry running

Application

in vacuum operation

Low-pulsation

transport of media

Optional

sensor-based operation monitoring

Low

noise emissions

Various

installation positions

Easy

installation

Field of application

Flow

rate: max. 600 m³/h

Head:

max. 98 m

Permissible

operating pressure: up to 16 bar

Temperature:

-50 °C to +140 °C

Viscosity:

up to 200 mm²/s