Power supply Three-phase voltage from 230V to 690V, 50Hz or

60Hz; suitable for use with an inverter from 20Hz to the base frequency, with

constant torque load profile. Polarity All polarities available. Conformity

with Standards and Regulations Low Voltage Directive 2006/95/EC; EN/IEC

60034-1; UL 1004-1, CSA C22.2 No.100, NEMA MG-1. Functioning Continual service

(S1) at maximum declared centrifugal force and electric power. Intermittent

services are also possible depending on the type of vibrator and the operating

conditions. For detailed information, contact our technical assistance office.

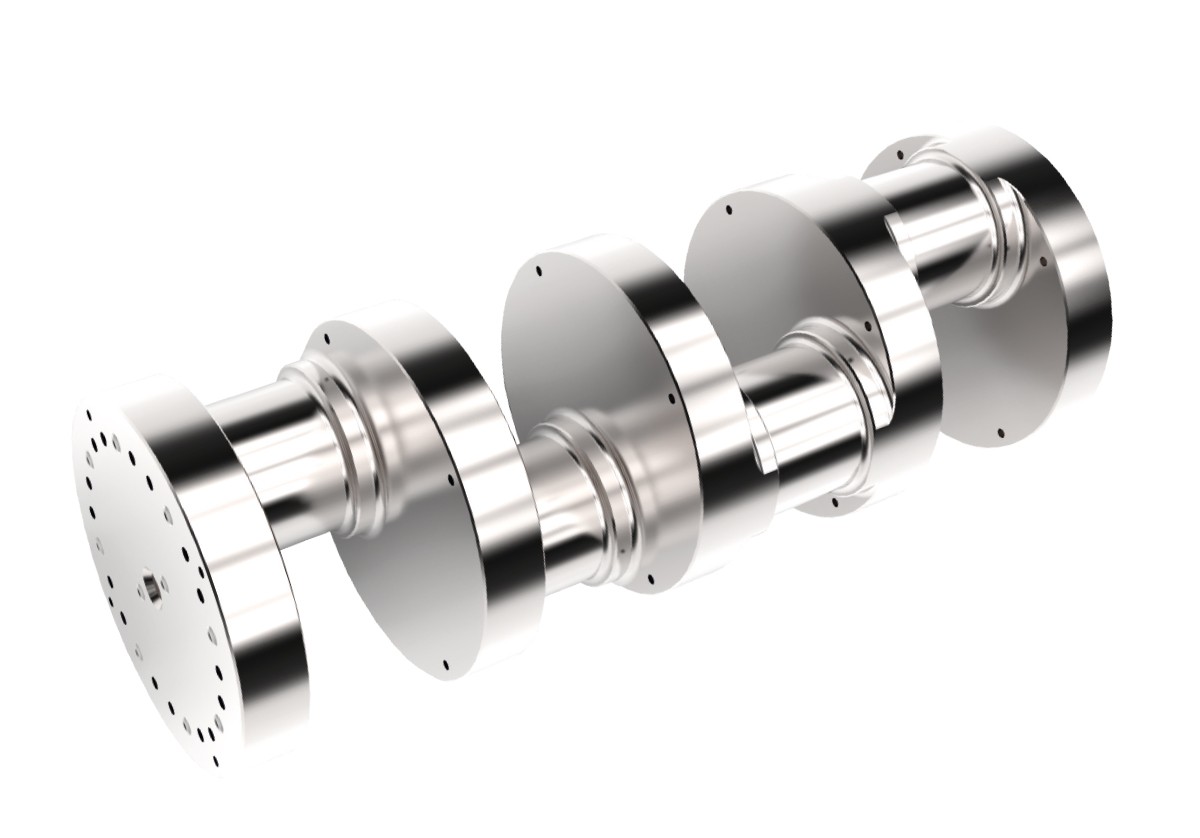

Centrifugal force Adjustable in a continuous linear way by varying eccentric

weight position. Mechanical protection Do be defined depending by type.

Protection against mechanical impacts IK 08 according to

IEC/EN 62262. Insulation class Class F (155°C), class H (180°C) on request.

Tropicalization Standard on all vibrators, with vacuum encapsulation up to gr.

AF 33 and 35, with “drop by drop” trickle system for larger sizes. Ambient

temperature From -20°C to +40°C. Versions for higher or lower temperatures are

available on request. Vibrator thermal protection With PTC rated thermistor

heat detectors 130°C. On request, thermistors with different temperatures and

anti-condensation heaters. Fixing of the vibrator In all positions and

therefore without restriction. Lubrication All vibrators are correctly

lubricated in the factory and do not require further lubrication at start-up.

Terminal box Large terminal box to facilitate

electrical connection. Special shaped terminals allow for the power supply

cable to be secured, whilst protecting it from loosening. Electric motor

Three-phase asynchronous type. Designed for maximum starting torques and torque

curves specific to requirements of vibrating machines. Insulated windings using

vacuum encapsulating up to size AF33 and 35 included; using the “drop by drop”

trickle system with class H resin for larger sizes. The rotor is die cast

aluminium Casing In high-tensile aluminium alloy up to size 60, in spheroidal

cast iron for larger sizes.