Exact process control

KIESELMANN control valves for liquids and gases regulate volume

flows and pressures in process plants. The selection of the appropriate valve

type depends on the application. The space-saving and cost-effective butterfly

valves with positioners are ideal for simple control tasks. For processes

requiring high control accuracy, KI-DS single-seat control valves are the right

choice

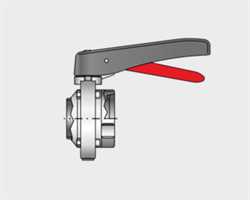

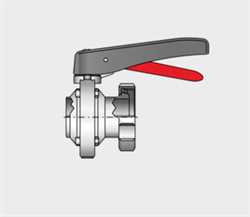

Butterfly valves with positioner: Space saving, cost-effective

Butterfly valves with positioner are the cost-effective solution

for simple control tasks in piping systems. The valve is actuated and regulated

by a digital electro-pneumatic positioner. The positioner, actuator and valve

form a closed control loop. A detailed description of the positioner can be

found

here.

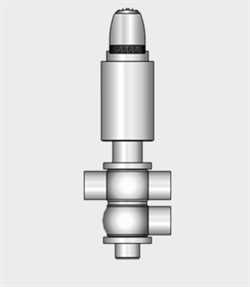

Single-seat

control valves: Highly precise and modular

The

versatile, hygienic single-seat control valves from KIESELMANN are available in

linear and equal-percentage versions. They are based on our proven KI-DS valve

concept and are suitable for sensitive production areas in the food and

beverage industry. The modular design with the large nominal diameter range

from DN 25 to DN 125 and the functionally graded flow coefficients offers

maximum flexibility - and the right valve for every application.

High

control accuracy and cavitation resistance

A major

advantage of our control valves is the replaceable cone and valve seat. If the

process conditions change, KIESELMANN control valves can be adapted quickly and

easily - without having to replace the complete valve. Within a nominal

diameter, the valves can be converted at any time to different flow

coefficients, control characteristics and seal types. With nominal pressures of

up to PN 16 as well as metallic and elastomeric sealing concepts, the valves

enable safe and precise process control and sealing.

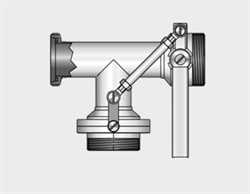

Electropneumatic

positioner

Positioners

with M12 round plug and Bluetooth and USB interface are available for all

control valve types. The setting of the control range can be made in the

higher-level control.

It is

even more convenient via the Bluetooth interface. This makes it possible to

configure the valve directly on site with a tablet or smartphone. This is

possible even if the valve is installed difficult to reach. This ensures the

direct access to the process that many users have requested.

• Three actuators with compatible connections

• Maintenance-free actuator with 5 years warranty

• Maintenance-friendly intermediate flange design

• Cost-effective

• Modularity

• Simple adaptation

• Flexible cone & replacement seat concept

• Elastomer sealing or metallic sealing

• Linear or equal-percentage control

Technical data

Sizes:

DN 15–120, 1"–4"

Seals:

EPDM HNBR FKM SIP

140°C, 30 min

SIP

110°C, 30 min

SIP 95°C, 30 min

Kv values:

0.4 – 160 m³/h

Materials:

in product contact 1.4404

/ AISI 316L

1.4542 / AISI 630

17-4PH

Product-contacting surfaces :

Ra ? 0.8 µm e-polished

Actuator:

- Diaphragm actuator - Lifting piston actuator

Operating pressure:

PN 16

Control air:

5.5-8 bar lower control air pressures on request

Operating temperature:

95 °C