Contamination-free

separation

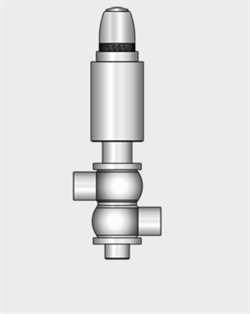

KIESELMANN

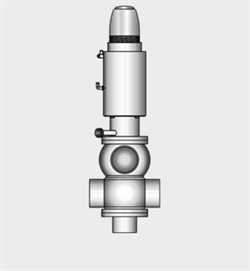

double-seat valves are the first choice to safely separate in automatic process

equipment, which does not belong together.

Our

double-seat valves are among the

most

modern,

safest valves

on the market. Two independently controllable valve plates with non-pressurised

leakage discharge prevent incompatible media from mixing. Product rearward

migrations of the valve disk seals are excluded. If a leak occurs contrary to

expectations, the medium flows out through the leakage gap without pressure.

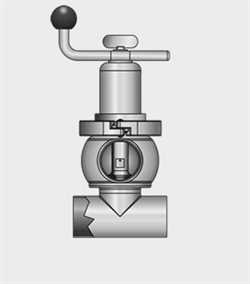

Split valve plates for maximum safety.

The easy

cleaning of the leakage space is performed by lifting the upper or lowering the

lower valve plate.

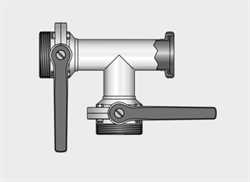

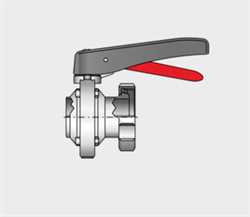

Everything

under control thanks to comprehensive

automation

optionsfrom sensor monitoring via PLC or ASI-BUS control head

through to emergency stop function and valve position indication. An ATEX

version is even available for gas and dust areas (Zones 1, 2 and 21, 22).

KIESELMANN

double-seat valves are characterised by low operating, maintenance and repair

costs.

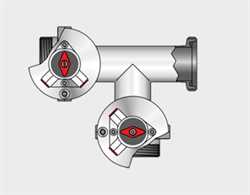

• Leakage-free opening

• Long seal life

• Pressure shock resistant

• Optimal cleaning functions

• Optional control heads PLC, AS-Bus, emergency stop function,

feedback, ATEX

• Safe product separation

• Extensive automation possibilities

• Sealing materials EPDM, HNBR, k-flex

Technical data

Sizes:

DN 25 -150 1"-4"

Seals:

EPDM SIP 140°C, 30

min FDA compliant

HNBR SIP 110°C, 30 min FDA

compliant

k-flex SIP 150°C, 30 min FDA

compliant

Pressure shock resistant:

up to 40 bar (closed valve position)

Materials:

in product contact 1.4404 / AISI 316L

not in product contact 1.4301 /

AISI 304

1.4307 / AISI 304L

Surfaces:

in product contact Ra ? 0.8 µm e-polished

not in product contact Ra

1.5–2.5 µm e-polished

Operating pressure:

DN 25 -100 max.

10 bar

DN 125 / 150 max. 6 bar

1"-4" max.

10 bar

Control air:

5.5 - 8 bar lower control air pressures on request

Operating temperature:

95 °C