Germs

and impurities don’t stand a chance

Unbeatably

aseptic! We have replaced the bellow seal with a diaphragm seal!

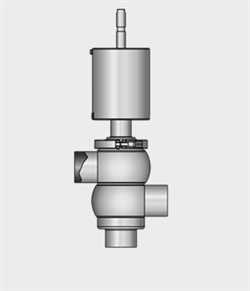

In order

to process microbiologically sensitive products safely and aseptically in

process systems, we have developed the GEMBRA aseptic valves. They combine

hygienic design and forward-thinking hybrid

technology.

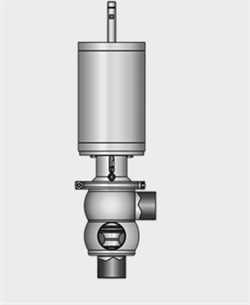

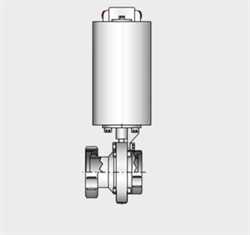

GEMBRA

stands for high-end stainless steel technology, excellent cleanability and a

safe, long-lasting diaphragm seal.

The aseptic valves are based on the geometric advantages of our proven seat

valve technology. This includes freedom from cavities and optimal idling

behaviour.

The

dome-free and gap-free GEMBRA valve concept meets the strict requirements of hygienic design. All seals in contact

with the product are made in our proven k-flex

sealing material for the highest temperatures and aggressive media. The sealing

system is characterised by a defined load and metallic stop in all components.

The process reliability is

maintained even at pressure peaks of up to 30 bar.

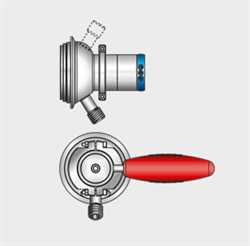

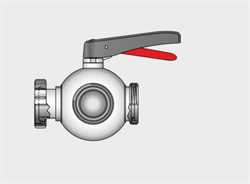

The

GEMBRA valves are available as single-seat valves, changeover valves, tank

outlet valves and leak-proof double-seat valves in various nominal diameters.

• Level inner surface/excellent cleanability

• Safe leakage detection

• Shockproof up to 30 bar

• Simple, cost-effective seal replacement

• Metallic diaphragm support

• Anti-adhesive k-flex/PTFE (FDA compliant) sealing material

Technical data

Sizes:

DN 40-80

(Product-contacting)Seals:

k-flex PTFE (FDA compliant)

Membrane pressure resistance:

maximum 30 bar

Materials:

in product contact 1.4404 / AISI 316L

not in product contact

1.4301 / AISI 304

Product pressure valve functions:

DN 40–65 maximum 10

bar

DN 80 maximum 8 bar

Control air

5.5–8 bar

Actuator:

Spring return, adjustable, optional end position feedback

Product temperature

maximum 95°C

Ambient temperature

+4° to +45°C

Sterilization temperature

maximum 140 °C, 30 min.