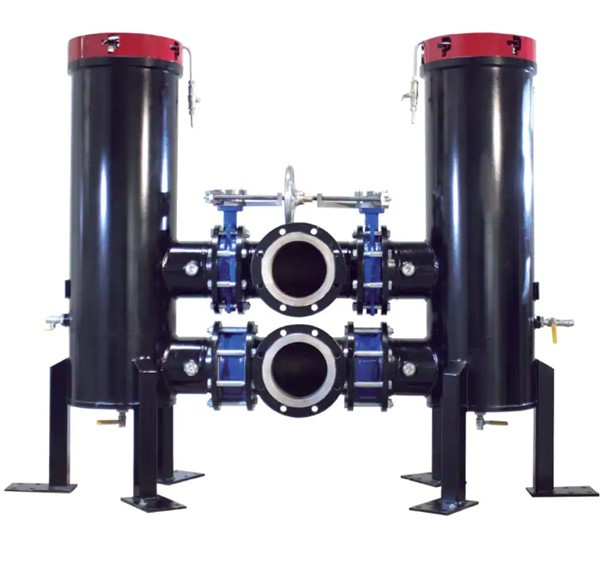

Low Pressure In-Line Duplex Filter - DF65 SeriesThe DF65 duplex filter has been designed especially for applications where

space is limited. The unique design allows the installation of the filter in

almost any position. Suitable for a max. flow 800 L/min and a max. pressure of

25 bar.

Technical

Specifications

Flow

Rate: 800 L/min, 500-1,000 L/min

Seal Material: Fluorelastomer

Mounting Type: Inline

Pressure Rating: 0-34

bar, 0-500 psi bar

Housing Material: Cast

iron (GSJ)

Full Product

Description

The DF65 duplex fılter has been designed

especially for applications where space is limited. The unique allows the installation of

the

fılter in

almost

any position. For very tight height limitations,

horizontal mounting position

will save on critical available space. Purpose-designed iprotect® elements contain a broad

filtration area providing low pressure loss, long service life and maximum protection even in cold conditions.

The duplex arrangement allows continuous operation and element service to be made when mmost suitable for the maintenance staff.P® family of fılter elements represent the next generation of patented fılter elements. a. Thanks to the patented

construction of every iprotect element,

the quality of fıltration is guaranteed, as no 'pirate

spare parts' can be used. This ensures

that the iprotect

element remains the truly protective 'DNA' of hydraulic

& lubrication systems. b. In addition to the ultimate

protection of the system, the iprotect family ensures that any environmental impact is minimised, by the retention

and reuse of the fılter element support

core. c. Finally, 'iprotect' the environment by reducing environmental waste, typically, by 50%. Typical

Applications:•

Gearbox lubrication systems• Turbine lubrication systems

•

Propulsion systems