Advantages

-Elements

available in different torsional stiffnesses

-Suited for highest speeds

-Adaptation to DIN or SAE

flanges or according to speci?cation

-Self-centering,

backlash-free and maintenance-free

-Compensation of axial,

radial and angular displacements

-Light-weight construction

through the use of high-strength aluminium

-Variable mounting lengths

through telescopic intermediate shafts

-For use up to TKN,

depending on the application

General Technical Description

Test benches have a wide

variety of applications in power transmission engineering. They are used to

determine properties of test objects in research, development, manufacturing

and quality assurance. The drive train components which are predominantly

tested on test benches include, but are not limited to, engines, gearboxes,

transmission elements and consumables. Given the multitude of testing tasks,

the specific requirements for couplings on test benches are quite diverse. The

TOK coupling system can be used in almost all applications. and on test benches

in particular. The wide range of flexible coupling elements, adaptations and

connection shafts ensures that a standard solution is almost always available

in a wide variety of different tasks. These can be complemented by specific

customised designs on request.

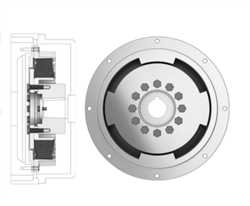

The

flexible element is designed to combine high torque transmission capacity with

high speed capability. Its torsional stiffness can be adapted to requirements

by selecting different types of rubber.

Bearings

or integrated joints support the loads arising from the connection between the

drive end and the output end. Cardan shafts, constant velocity (CV) shafts and

compact shafts are available as connections which also compensate for

displacements. Adaptive designs are based on the standard DIN or SAE ?ange

connection dimensions, the CV shaft joints and the torque measuring flanges.

The couplings cover a torque range from approx. 100 Nm at 10 000 min-1 up to 70

000 Nm at 1 800 min-1.