Produktname: Anderson Greenwood 4130 Atmospheric Pressure Relief Valve

Marke: Anderson Greenwood

Produktcode: 4130

Stichwörter: Anderson Greenwood

Anderson 4130 Pressure Relief Valve

Greenwood 4130 Atmospheric Pressure Valve

4130 Atmospheric Relief

Anderson Greenwood Relief Valve

Anderson Greenwood 4130 Atmospheric Pressure Relief Valve

Greenwood 4130 Pressure Relief Valve

Anderson Greenwood Relief Valve

Atmospheric Pressure Relief Valve

Greenwood 4130 Atmospheric Pressure Valve

Anderson 4130 Atmospheric Pressure Relief

Greenwood Relief

Anderson 4130 Atmospheric Relief Valve

Greenwood 4130 Atmospheric Pressure

Anderson Greenwood Pressure Valve

Anderson Atmospheric Pressure Valve

Greenwood Atmospheric Relief Valve

Anderson Greenwood Atmospheric Relief

Anderson Pressure Valve

Anderson Greenwood 4130 Relief

4130 Pressure Relief

Atmospheric Pressure Relief Valve

Interessieren Sie sich für das Produkt Anderson Greenwood 4130 Atmospheric Pressure Relief Valve vom Hersteller Anderson Greenwood mit dem Code 4130? Kontaktieren Sie uns jetzt und holen Sie sich ein Angebot. Imtek Engineering, der schnellste und zuverlässigste Lieferant von Industrieausrüstung der Welt, wird Ihnen das beste Angebot machen!

Angebot per E-Mail erhalten: info@im-tek.com

Holen Sie sich jetzt ein Angebot für Anderson Greenwood 4130 Atmospheric Pressure Relief Valve von unserem Live-Support-Team!

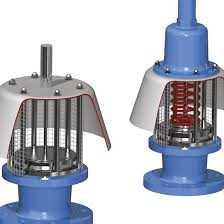

High capacity weight or spring loaded pressure relief valves that vent to atmosphere.Designed to work closer to a tank's MAWP, increasing productivity, reducing emissions and product evaporationncreased flow capacities reduce the required valve size and the corresponding connections and piping costs.Fully open at 10% overpressure, enabling setting close to MAWP and minimizing tank emissions.Large body for increased capacity providing high flow performance for full conformance to API2000/ISO28300.Leakage rate of 0.5 scfh (0.015 Nm3 /hr) or less at 90% of setpoint.Weight or spring loaded models available.Choice of body materials.Modular design enables all components to be removed and replaced in-situ for quicker, simpler maintenance.Optional ‘all-weather’ coating prevents frozen condensate build-up and sticking of vital components in cold weather applications.