Produktname: Gefa TYPE HYDRAULIC Control Unit

Marke: Gefa

Produktcode: TYPE HYDRAULIC

Stichwörter: Gefa

HYDRAULIC Unit

HYDRAULIC Control Unit

TYPE HYDRAULIC Control

Gefa TYPE Control

Control

Gefa TYPE Unit

Gefa HYDRAULIC

Gefa Control

Gefa TYPE HYDRAULIC Control

Gefa HYDRAULIC Unit

Gefa TYPE HYDRAULIC Unit

TYPE HYDRAULIC

Control Unit

Gefa TYPE Unit

HYDRAULIC Control Unit

Gefa HYDRAULIC Control

Gefa TYPE HYDRAULIC Unit

Control Unit

Interessieren Sie sich für das Produkt Gefa TYPE HYDRAULIC Control Unit vom Hersteller Gefa mit dem Code TYPE HYDRAULIC? Kontaktieren Sie uns jetzt und holen Sie sich ein Angebot. Imtek Engineering, der schnellste und zuverlässigste Lieferant von Industrieausrüstung der Welt, wird Ihnen das beste Angebot machen!

Angebot per E-Mail erhalten: info@im-tek.com

Holen Sie sich jetzt ein Angebot für Gefa TYPE HYDRAULIC Control Unit von unserem Live-Support-Team!

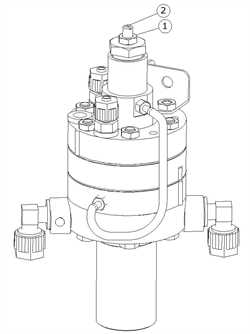

The automatic flushing cycle described below takes a few seconds and does not interrupt the supply of process water. Water flows from the inlet through the coarse and fine screens to the outlet. At a pre-set pressure differential (0.5 bar —7 psi), the rinse controller activates the piston and opens the flushing valve. The water from the rotor chamber flows out the drain. The pressure in the rotor chamber drops, releasing a strong flushing stream that flows through the filter.This drop in pressure and corresponding release of the backflush stream create suction on the nozzle tips. This effect actuates spot cleaning directly in front of the openings of each nozzle on the inner surface of the fine screen. The water and particles passing through the hydraulic rotor cause the dirt collector to rotate, and the piston moves in an axial direction to the opposite end of the filter.The combination of rotational and axial movement of the dirt collector assembly ensures that the nozzles sweep the entire inner surface of the fine screen.When the first stroke is completed, the flushing valve closes and after a very short interval the rinse controller activates the second backflush stroke. The dirt collector assembly spins, moving with the piston in the opposite direction and returning to its original position.This self-cleaning process takes between 8–15 seconds, depending on the operating pressure.