EDUR-multiphase pumps

are designed to supply integrated liquid-gas mixtures and to generate dispersions.

They enable the supply of up to 30% gas proportions.

Fields of Application

and Conveyed Fluids

EDUR-multiphase pumps are

used in

water and wastewater technology as

well as in

different industrial technologies.

Typical fields of application are flotation plants acc.

to VDMA specification 24430, ozonization, water treatment, crude

oil water separation, fuel production as well as the general process

technology. Multiphase pumps

supply liquid-gas mixtures and

enrich

liquids with gases, such as air, oxygen or ozone.

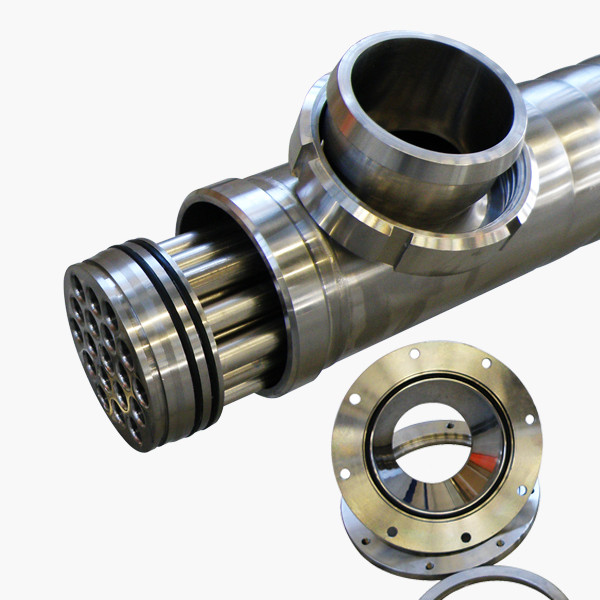

Functionality

The pump hydraulic differs in

terms of structure and mode of operation from conventional centrifugal pumps

and thus allows throttled-down operation on the suction side without cavitation

arising that is critical when using standard centrifugal pumps.

Gas

proportions up to 30% are self-primed and safely

co-supplied. In addition,

dynamic mixing and

an

excellent gas saturation is guaranteed by

those pumps.

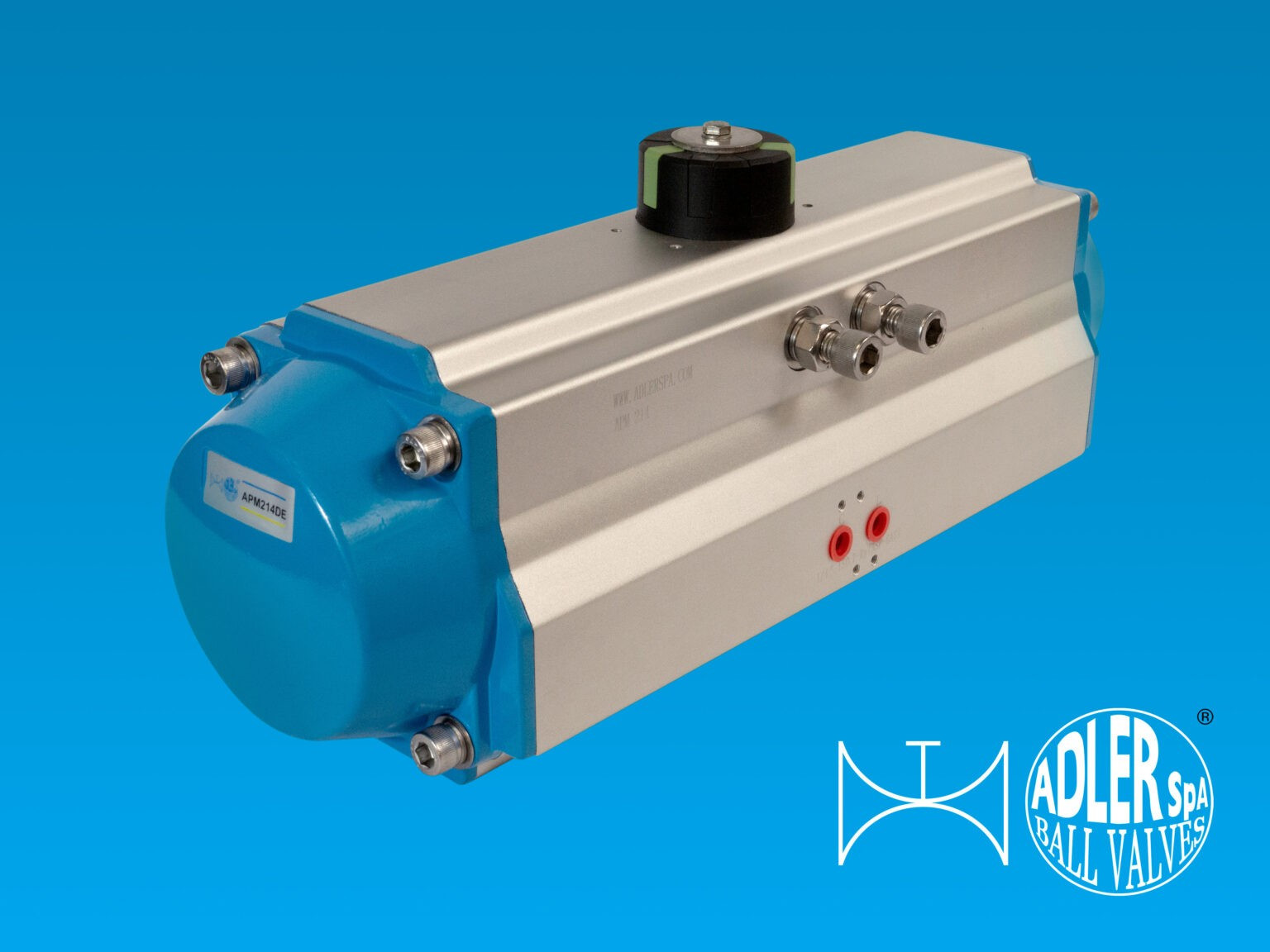

Variants of

EDUR-Multiphase Pumps

Multiphase pumps are also referred to as flotation pumps, DAF pumps or

(gas) saturation pumps. EDUR-series for multiphase pumps are the PBU and LBU. They are available

in a variety of construction styles and materials, such as grey cast

iron, bronze or stainless steel as well as with various shaft seal systems and

drive solutions. As required, we deliver customer-specific configurations. Of course, we

can also provide certificates of all authorized classification societies and necessary test reports.AdvantagesImplementing EDUR-multiphase pumps eliminates the need for expensive

compressor systems, pressure vessels, control units, valves and the

corresponding maintenance costs. Gaseous fluids can be fed directly into the pump

within the partial flow process. The special, open and axial thrust-free

impeller design of these pumps guarantees this efficient process design.As with all EDUR-pumps, multiphase pumps stand out due to their efficiency, economy

and reliability. Moreover, we would like to emphasize the following product advantages as

well as technical characteristics:

Gas

enrichment of liquids and conveyance of gas-loaded liquids e.g. with air

or ozone

Direct

gas entry into the suction line

Dynamic

mixing

Excellent

gas saturation

Perfect

dispersion with bubble sizes between 30 and 50 μm after expansion

Optimized

size of pressure nozzle for low pipe friction losses and velocity head

difference

Significant

reduction of plant components

Cost-

and energy-efficient operation in flotation plants

Optional

sensor-based operation monitoring

Low

noise emissions

Easy

maintenance

Technical data

Flow

rate: max. 60 m³/h

Head:

max. 250 m

Permissible

operating pressure: up to 40 bar

Gas

conveyance: up to 30%

Temperature:

-50 °C up to +140 °C

Viscosity:

up to 115 mm²/s