Fields of Application and Conveyed Fluids

EDUR-self-priming centrifugal pumps are mainly used within energy technology, water and wastewater technology, cooling technology, industrial technology as well as in liquefied gas applications.In contrast to non-self-priming pumps, self-priming centrifugal pumps are able to ventilate the suction line and to self-prim lower-lying liquids. Also gas-emitting fluids can be supplied reliably. The pumps stand out due to low suction times and high efficiency grades to guarantee reliable operation. Special characteristics are also the high air flow rate and wear resistance.Self-priming pumps from EDUR are suitable for the supply of slightly contaminated water, cooling water, emulsions, oils and fuels such as kerosene, petrol and diesel.

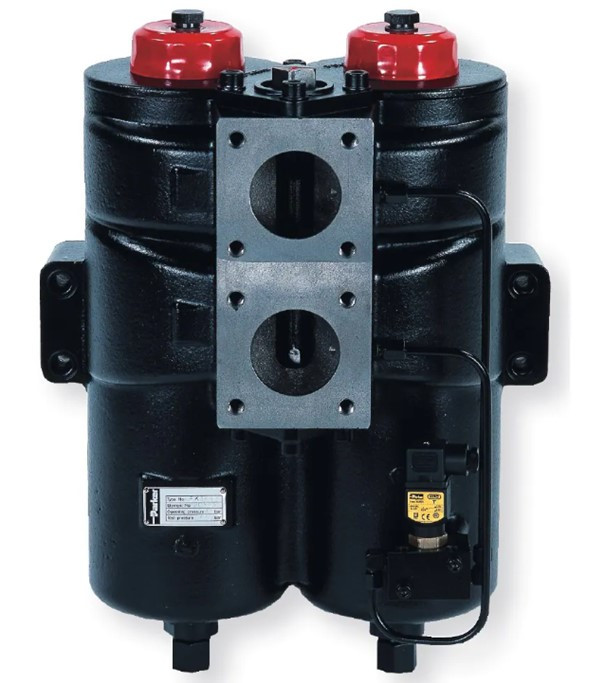

Variants of the Self-Priming EDUR-Centrifugal Pumps

EDUR offers high-quality self-priming centrifugal pumps with our S, SUB and E series. The pumps are available in a variety of construction styles and materials (e.g. grey cast iron, bronze or spheroidal graphite iron) as well as with various sealing systems and drive solutions. As required, we deliver customer-specific configurations. Of course, we can also provide certificates of all authorized classification societies and necessary test reports.

Advantages

As all EDUR-pumps, our self-priming centrifugal pumps stand out due to their efficiency, economy and reliability. Moreover, further product advantages are outlined below:High energy efficiencyIntegrated jet pump or formation of mixtureLow flow velocitiesLow internal friction lossLow NPSH (Net Positive Suction Head) valuesTechnical superiorityAxial thrust-free, open or load-relieved, closed impellersCompensation of the radial forces due to diffuser elements in the ring housingProcess safetySelf-primingPossible conveyance of gas-loaded liquidsAssembly-friendlyHorizontal designBlock and base plate designTechnical dataFlow rate, max. 170 m³/hPermissible operating pressure up to 16 barTemperature -40° C up to +90° CViscosity up to 115 mm²/s

CHARACTERISTIC CURVES