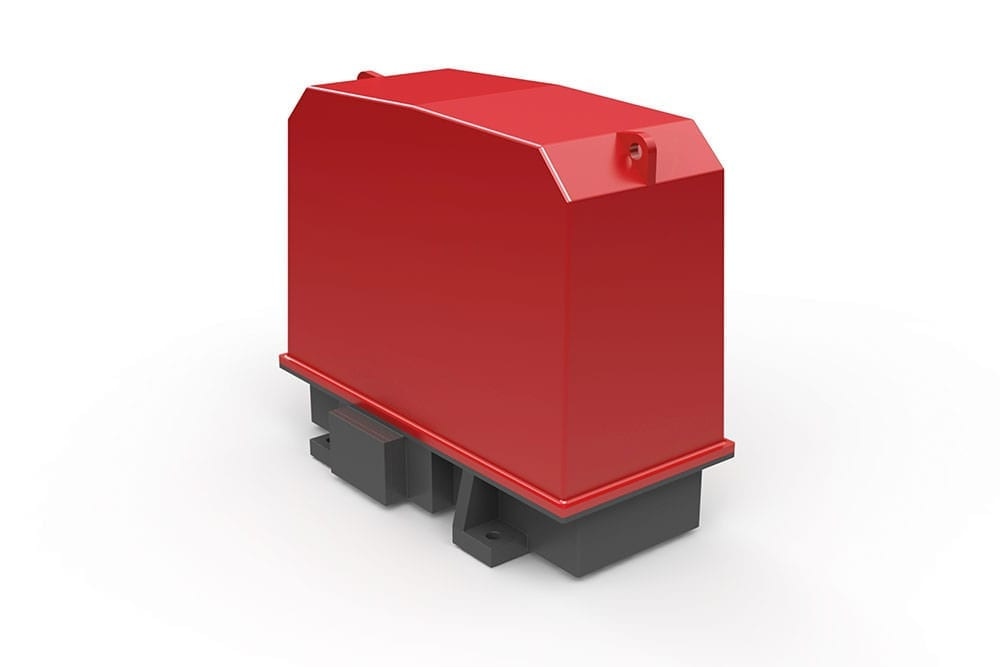

Fisher™ V500 Eccentric Plug Valve

The Fisher V500 rotary control valve combines globe valve ruggedness with the efficiency of a rotary valve. It is designed to control erosive, coking, and other hard-to-handle fluids, providing either throttling or on/off operation.

Specifications

CertificationsSIL capable, ATEX, CUTR, PED, CRN, Fugitive Emission, NACECritical ServiceNoise Abatement, Cavitation, Dirty Service, Erosive, Low Flow, General ServiceFlow CharacteristicsLinearMaterialCarbon Steel, Stainless, Duplex, AlloyOperating TemperatureStandard TemperaturePressure ClassPN, ASMEProcess Connection TypeFlangedShutoff ClassClass IV (FCI 70-2)Valve SizeNPS 1, NPS 1-1/2, NPS 2, NPS 3, NPS 4, NPS 6, NPS 8Valve Size StandardNPS, DNOther ConfigurationsContact your local Emerson business partner or sales office to learn about additional specifications or options for this product.

Features

Self-centering seat ring and rugged plug allow forward or reverse flow with tight shutoff in either flow direction.Integral valve body flanges mate with many different classes of pipeline flanges, satisfying a variety of piping requirements.Streamlined flow passages, rugged components, and a wide choice of erosion-resistant trim materials all promote long, dependable service life in erosive applications.Path of eccentric plug minimizes contact with seat ring when opening, reducing seat wear and friction.Specially selected trim materials and body coatings help to withstand oil sands, furnace feed, and other highly erosive applications.Durable, solid metal or VTC seat ring and valve plug shutoff tightly without deforming plug arms or employing thin ball seals.No special orientation, precision clamping or repetitive centering of valve plug and seat ring is required when tightening the retainer, promoting accurate alignment and easy assembly.