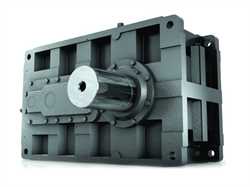

Nom du Produit: Benzlers G Series Helical Industrial Gearboxes

Marque: Benzlers

Code Produit: G Series

Mots-clés: Benzlers

Benzlers G

G Series Industrial

Series Helical Industrial

G Series Helical

Helical Gearboxes

Benzlers G Industrial Gearboxes

G Series Helical

G Series Industrial

Series Industrial

Benzlers Series Helical Industrial Gearboxes

G Helical Gearboxes

Benzlers G Gearboxes

Industrial Gearboxes

Benzlers G Series Industrial

Benzlers Series Industrial Gearboxes

Benzlers G Helical Gearboxes

Benzlers Series Helical

Benzlers Industrial Gearboxes

Benzlers G Series Helical Industrial

Helical Industrial Gearboxes

Êtes-vous intéressé par le produit Benzlers G Series Helical Industrial Gearboxes du fabricant Benzlers avec le code G Series? Contactez-nous maintenant et obtenez une offre. Imtek Engineering, le fournisseur d\'équipements industriels le plus rapide et le plus fiable au monde, vous offrira la meilleure offre!

Obtenez une offre par e-mail: info@im-tek.com

Obtenez une offre pour Benzlers G Series Helical Industrial Gearboxes de notre équipe de support en direct maintenant!

Features & BenefitsThis product takes advantage of our many years of accumulated design expertise together with the use of high quality materials and components, and has the following features & benefits:Case hardened and ground helical gears, and hard finished spiral bevel gears have optimised gear geometry to maximise strength and efficiency, and to minimise noise and vibration.Horizontal split case design for ease of maintenance.Large diameter output shaft and bearings to maximize overhung load capacity.Innovative modular construction has minimised part count to maximise availability of product.FeaturesBenefitsLip, Labyrinth and Face Seal on input, Lip Seal and Labyrinth on output shaftBetter sealing for harsher environmentsVertical units have a Drywell sealing arrangementNo head of oil resting on the output sealSpherical roller bearings throughout (tapers roller bearings on bevel pinion shaft)Provides longer lifeLarge diameter output shaft, higher over hung loadsBest option for stirrer applicationsHollow bore and shrink disc options gives versatility in mountingHollow bore reduces alignment issuesExternal hold back, allows for inspectionReduced down timeAtex compliantCan be supplied against Group 2 or 3 for surface industries in designated Hazardous locations, Zones 1 and 2 for gases, vapours and mists and Zones 21 and 22 for dust.Product OptionsUnit Sizes:14, 15, 16, 17, 18, 19, 21 and 22Input Power:Up to 1,860 kW (2,494 HP)Output Torque:Up to 162,000 Nm (1,433,821 lb.in.)Gear Ratios:Up to 315:1 in multistage and up to 70,000:1 in combined formOutput Shaft:Up to 240mm (9.45 in.)Motor Sizes:IEC Frames from 200 to 315; NEMA Frames from 254 to 445