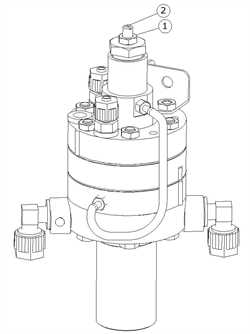

The Semi-Automatic assemblies provide a quick and efficient way for cleaning manual filters. The Scanaway and Brushaway are add-on assemblies built for upgrading plastic filters to semiautomatic operation by adding simple turn-of-a-handle cleaning mechanism to the filter’s screen. Upgrading a manual filter to semi-automatic operation eliminates the need for turning off the water and extracting the filter screen for rinsing, with the semi-automatic assembly the process flow is not interrupted during operation. The semi-automatic assemblies are fitted with a Clogging Indicator for visually monitoring the status of the filter element without disrupting the water flow. A red button pops up from the indicator when the differential pressure across the screen reaches 0.5 bar (7 psi).

DETAILS

Housing: Polyacetal/PolyamidScreen: Stainless steelFiltration degree: 50, 80, 100, 130, 200, 300, 500 micronPressure: min. 2 bar / max. 10 barTemperature: max. 60 °CNominal size: DN 50 - DN 80

HOW THE “SCANAWAY” ASSEMBLY WORKS

The Scanaway assembly consists of a suction-scanner, a hollow pipe with suction nozzles, that is facing the inner side of the screen. Outside the filter a handle is connected to the suction-scanner, allowing the turning of the scanner in a spiral movement so it rotates inside the screen surface without touching the screen mesh. Opening the exhaust valve at the filter lid creates low pressure conditions in the suction scanner, which cause the scanner nozzles to suck in the dirt particles from the screen surface and expel the dislodged particles out through the exhaust valve. Scanning is done during the filtration process without having to stop the flow of process water through the filter.

HOW THE “BRUSHAWAY” ASSEMBLY WORKS

The Brushaway assembly consists of nylon brushes fitted on a frame and inserted into the filter screen. A simple handle, outside the filter, allows brushing away particles from the inner screen surface and expel them out from the filter through the exhaust valve. Brushing is done during the filtering process without having to stop the flow of process water through the filter.