Applications

Continuous flow indication without power supply

Thirteen different versions and corrosion resistant materials make the products suitable for a broad range of applications

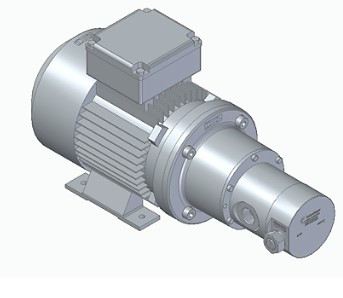

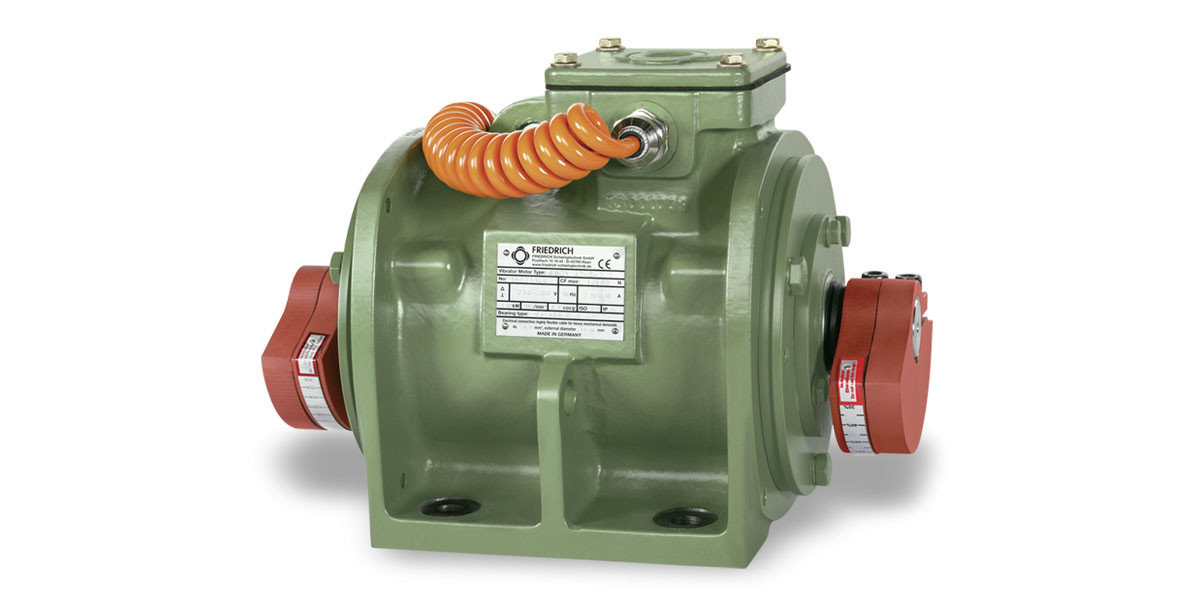

Machine building, chemical industry, pharmaceutical industry, medical engineering

Cooling systems and cooling circuits, transformers, central lubrication systems and recirculating oil lubrication systems

Research and development

Special features

High switching accuracy and functional safety

Large switching range, low switch hysteresis

Continuous switch point setting by the operator

Viscosity compensated models available

Explosion-protected versions

Description

The model FWS flow monitors are used for the display and monitoring of the flow of liquid and gaseous media, e.g. in cooling systems and cooling circuits of welding machinery, laser and piping systems, dosing systems, pumps, compressors, hydraulic systems, high-pressure plants and many more.

The flow monitors operate in accordance with the float-body measuring principle. A float body is guided within a cylindrical slotted nozzle or in a cylindrical measuring tube. A reed contact is mounted outside of the flow circuit.

The reed contact is cast into a continuously adjustable case (switch case) and thus is protected from external influences.

The flowing medium moves the float body in the direction of the flow. When the float body, with its integrated magnet, reaches the position of the reed switch, this closes. When the flow rate rises, the float body moves further in the direction of the flow, maximally until it reaches a stop. This stop prevents the float body from being driven beyond the switching range of the reed switch (bistable characteristic).