Advantages

Direct connection to SAE J 620, adaptation to other flywheels on requestCompensation of axial, radial and angular displacementsBacklash-free and maintenance-freeCan also be used for bell-house typeFreely pluggable splined shaft for ease of assemblyVarious elastomers for adaptation to resonance condition and temperature (-40 °C to +120 °C)Linear torsional deflection characteristic

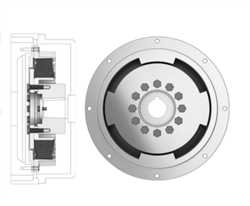

General Technical Description

The highly flexible TOK coupling has been specially designed for applications requiring extremely low torsional stiffness. Furthermore it is particularly well suited to the compensation of axial and radial displacements of flexibly mounted engines. The wide range of flexible coupling elements and adaptive designs provides standard solutions for a wide variety of different tasks. These can be complemented by specific customised designs on request.

The flexible element is designed to combine high torque transmission capacity and high displacement capacity with high speed capability. Its stiffness can be adapted to requirements by selecting different rubber qualities.

The extremely low torsional stiffness allows for a safe and over critical layout of the coupling. During start and stop operations, the resonance range is passed through quickly, and excellent decoupling between the combustion engine and the driven machine is achieved over the entire operating speed range.

The TOK coupling enables direct connection between the engine and the driven machine and is capable of compensating for misalignments resulting from the flexible mounting without requiring any additional components. Restoring forces remain within the permissible limits despite good displacement capability, with a significant reduction in assembly effort and smooth running of the drive (noise reduction).