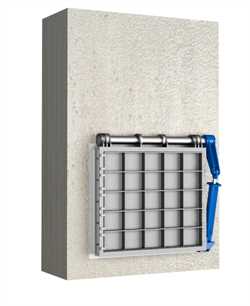

For use in single-line lubrication systems

The SKF Lincoln SLC metering device is designed for use in high-pressure single-line lubrication systems and features a modular design. Also, delivery volume can be adjusted via metering screws, helping to ensure each lubrication point receives the required amount of lubricant. Featuring a spring-reset control piston, the metering device has a high venting capability compatible with greases up to NLGI 2. The SLC offers easy configuration to meet your needs, including different output quantity, fitting and adjustment options.

With the most compact construction in its class, the SLC is suitable for many applications in renewable energy, construction, mining as well as in heavy industry.Features and benefits

High venting capability

Wide delivery volume range

Compact construction

Easy to monitor and maintain

Simplified failure analysis

Reduced risk of leaks

Reliable operation in harsh conditions with a wide operating temperature range

Patented design and functionality

Easy to clean

applications

Renewable energy

Construction and mining

Heavy industry

Similar features SLC1 and SLC2 | Function principle | Single-line metering device with spring loaded control pistons and double acting delivery pistons |

| Lubricant | Grease up to NLGI 2 |

| Operating temperature | –40 to +100 °C | –40 to +212 °F |

| System pressure | 150–315 bar | 2 150–4 600 psi |

| Relief / venting pressure | max. 68 bar | max. 990 psi |

| Lubricant inlet connection | G3/8 or 3/8" NPTF |

| Lubricant inlet fittings for tube O.D. | 8, 10, 12 mm or 1/4, 3/8, 1/2" |

| Material | Steel |

| Corrosion protection class (DIN EN ISO 12944) | C3 |

| Mounting position | any, preferable vertical |

Varying features

| SLC1 | SLC2 |

|---|

| Number of lubricant outlets | 1–12 | 1–6 |

| Delivery volume per outlet and stroke |

| Pre-set | 0,1; 0,15; 0,2;

0,25; 0,3; 0,4;

0,5; 0,6; 0,7 cm³ | 0.0061; 0.0091; 0.012;

0.015; 0.018; 0.024;

0.03; 0.036; 0.043 in³ | 0,2 ; 0,3; 0,4;

0,5; 0,6; 0,8;

1,0; 1,2; 1,4 cm³ | 0.012 ; 0.018; 0.024;

0.03; 0.036; 0.049;

0.06; 0.073; 0.085 in³ |

| Adjustable | 0,1–0,7 cm³ | 0.0061–0.043 in³ | 0,2–1,4 cm³ | 0.012–0.085 in³ |

| Lubricant outlet connection | 6 mm | 1/4" OD | 6, 8, 10, 12 mm | 1/4, 3/8 or 1/2" OD |

| Outlet thread |

|

| G1/4 or 1/4" NPTF |

|

| Dimensions | 12 outlet basic version | 6 outlet basic version |

| 144 × 135 × 50 mm | 5.67 × 5.31 × 1.97 in. | 169 × 132 × 40 mm | 6.65 × 5.2 × 1.57 in. |

Visual memory indicators | Function principle | Magnetic based reset indicator with red fault indicating ring and plastic protection cap |

| Material | Stainless steel |

| Operating temperature | –20 to +70 °C | –4 to +158 °F |

Electrical performance indicators | Function principle | Electronic piston detector |

| Material | Stainless steel |

| Corrosion protection class (DIN EN ISO 12944) | C5 |

| Operating temperature | –40 to +85 °C (–40 to +185 °F) |

| Design | 3 wire DC PNP, 2 wire DC PNP/NPN |

| Output function | NO-contact |

| Operating voltage | 10–36 DC, supply class 2 per cULus |

Protection class

| IP65 |

| Power consumption | max. 5 mA |

| Connection | M12x1-4 pole |

| Standard | CE, UL, CSA, E1 |

Order example

The product can be configured using a configuration code. The order example shows one possible part number and its explanation. |

SLC1G3B-1RGBBR-EXM |

Metering device SLC

Design size 1

BSP thread for metric tubing

Corrosion class C3

With four fixed metering screws and two adjustment screws at top and 6 visual indicators at bottom

Number of sections: 6 Metering volume per stroke, in total 11 outlets

Section 1: 0,2 cm³ (0.012 in³) (cross-porting 2x0,1 cm³ (2x0.0061 in³)

Section 2: 0,1–0,7 cm³ (0.0061–0.043 in³)

Section 3: 0,4 cm³ (0.024 in³)

Section 4: 0,1 cm³ (0.0061 in³)

Section 5: 0,1 cm³ (0.0061 in³)

Section 6: 0,1–0,7 cm³ (0.0061–0.043 in³)

Lubricant inlet connection left: Straight fitting for tube ?10 mm, joint with EO2

Lubricant inlet connection right: closed

Lubricant outlet connection: 11 tube ?6 mm, plug-in type, (5 odd outlets with extension)

|

You can configure the product using the CAD configurator below. This will give you a specific order number. |

| The product can be configured using a configuration code. The order example shows one possible part number and its explanation. |

| SLC1G3B-1RGBBR-EXM | Metering device SLCDesign size 1BSP thread for metric tubing Corrosion class C3 With four fixed metering screws and two adjustment screws at top and 6 visual indicators at bottom Number of sections: 6 Metering volume per stroke, in total 11 outlets Section 1: 0,2 cm³ (0.012 in³) (cross-porting 2x0,1 cm³ (2x0.0061 in³) Section 2: 0,1–0,7 cm³ (0.0061–0.043 in³) Section 3: 0,4 cm³ (0.024 in³) Section 4: 0,1 cm³ (0.0061 in³) Section 5: 0,1 cm³ (0.0061 in³) Section 6: 0,1–0,7 cm³ (0.0061–0.043 in³)Lubricant inlet connection left: Straight fitting for tube ?10 mm, joint with EO2 Lubricant inlet connection right: closed Lubricant outlet connection: 11 tube ?6 mm, plug-in type, (5 odd outlets with extension) |

| You can configure the product using the CAD configurator below. This will give you a specific order number. |