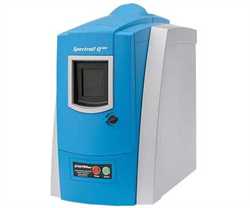

Produktname: Biolab Spectroil Q100 Oil & Fuel Elemental Analysis Spectrometer

Marke: Biolab

Produktcode: Spectroil Q100

Stichwörter: Biolab

Oil & Fuel Elemental Analysis Spectrometer

Interessieren Sie sich für das Produkt Biolab Spectroil Q100 Oil & Fuel Elemental Analysis Spectrometer vom Hersteller Biolab mit dem Code Spectroil Q100? Kontaktieren Sie uns jetzt und holen Sie sich ein Angebot. Imtek Engineering, der schnellste und zuverlässigste Lieferant von Industrieausrüstung der Welt, wird Ihnen das beste Angebot machen!

Angebot per E-Mail erhalten: info@im-tek.com

Holen Sie sich jetzt ein Angebot für Biolab Spectroil Q100 Oil & Fuel Elemental Analysis Spectrometer von unserem Live-Support-Team!

Spectroil Series are easy to use, reliable and the workhorses of commercial and military oil analysis laboratories that require the rapid analysis of wear metals, contaminants and additives in lubricants. It measures trace quantities of elements dissolved or suspended as fine particles in natural or synthetic petroleum based products using the time-tested and reliable rotating disc electrode (RDE) technique. The Spectroil is the ideal spectrometer for the in-service oil analysis laboratory because technology has made it smaller and the addition of an innovative CCD optical system has made it more flexible for even the most exotic in-service oil analysis applications. The standard configuration is equipped and calibrated for 22 wear metals, contaminants and additives. Additional elements can be added at any time, even in the field and if your application suddenly calls for unusual elements such as niobium, lithium or rhodium. An external computer with current Windows software controls the system. The additional capability to analyze engine coolants is available as an option. Provides an early warning of abnormal wear Conforms to ASTM Standard Test Method D6595 & D6792 requirements No sample preparation 30 second analysis time Bench-top and transportable Analyzes all elements simultaneously Always ready to analyze samples Simple to operate without special training or background Standard and readily available consumables Requires no special utilities or gases, only AC power