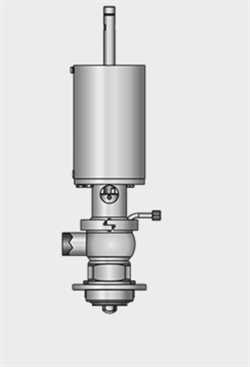

Produktname: Kieselmann 5859 S GEMBRA Aseptic Tank Outlet Double-seat Valve

Marke: Kieselmann

Produktcode: 5859 S

Stichwörter: Kieselmann

GEMBRA Aseptic Tank Outlet Double-seat Valve

Interessieren Sie sich für das Produkt Kieselmann 5859 S GEMBRA Aseptic Tank Outlet Double-seat Valve vom Hersteller Kieselmann mit dem Code 5859 S? Kontaktieren Sie uns jetzt und holen Sie sich ein Angebot. Imtek Engineering, der schnellste und zuverlässigste Lieferant von Industrieausrüstung der Welt, wird Ihnen das beste Angebot machen!

Angebot per E-Mail erhalten: info@im-tek.com

Holen Sie sich jetzt ein Angebot für Kieselmann 5859 S GEMBRA Aseptic Tank Outlet Double-seat Valve von unserem Live-Support-Team!

Germs and impurities don’t stand a chance Unbeatably aseptic! We have replaced the bellow seal with a diaphragm seal! In order to process microbiologically sensitive products safely and aseptically in process systems, we have developed the GEMBRA aseptic valves. They combine hygienic design and forward-thinking hybrid technology. GEMBRA stands for high-end stainless steel technology, excellent cleanability and a safe, long-lasting diaphragm seal. The aseptic valves are based on the geometric advantages of our proven seat valve technology. This includes freedom from cavities and optimal idling behaviour. The dome-free and gap-free GEMBRA valve concept meets the strict requirements of hygienic design. All seals in contact with the product are made in our proven k-flex sealing material for the highest temperatures and aggressive media. The sealing system is characterised by a defined load and metallic stop in all components. The process reliability is maintained even at pressure peaks of up to 30 bar. The GEMBRA valves are available as single-seat valves, changeover valves, tank outlet valves and leak-proof double-seat valves in various nominal diameters. • Level inner surface/excellent cleanability • Safe leakage detection • Shockproof up to 30 bar • Simple, cost-effective seal replacement • Metallic diaphragm support • Anti-adhesive k-flex/PTFE (FDA compliant) sealing material Technical data Sizes: DN 40-80 (Product-contacting)Seals: k-flex PTFE (FDA compliant) Membrane pressure resistance: maximum 30 bar Materials: in product contact 1.4404 / AISI 316L not in product contact 1.4301 / AISI 304 Product pressure valve functions: DN 40–65 maximum 10 bar DN 80 maximum 8 bar Control air 5.5–8 bar Actuator: Spring return, adjustable, optional end position feedback Product temperature maximum 95°C Ambient temperature +4° to +45°C Sterilization temperature maximum 140 °C, 30 min.