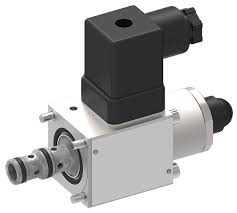

Type:

cartridge

Function:

pressure-reducing

Other characteristics:

two-stage, proportional, 3-way, compact

Temperature:

Max.: 70 °C (158 °F)

Min.: -25 °C (-13 °F)

Pressure:

210 bar (3,045.8 psi)

DN:

4 mm (0.157 in)

Flow rate:

10 l/min (3 us gal/min)

Description

Series DDRRZ-70… prop. 3-way pressure-reducing cartridges are direct acting, spool-type, push-in cartridges and are available in size 4. They reduce the outlet pressure in A as a function of the control current and independently of the inlet pressure in P. In the initial position (solenoid de-energised) the inlet of the 3-way pressure-reducing cartridge is shut off and the outlet is connected to tank (port A ? T). In control mode, the connection P ? A opens until the pressure in port A reaches the preset level. If the pressure rises above the preset level, the control spool opens the A ? T connection until balance is attained. Two pressure ranges are available. To accommodate a maximum operating pressure (inlet pressure) of pmax 210 bar, the “H” model must be used. With other models the maximum operating pressure is dependent on the pressure range. These 3-way pressure- reducing cartridges are predominantly used for reducing a system pressure in mobile and industrial applications. They are suitable for controlling larger directional valves, where they can be incorporated in the valve body or directly in the end covers, for example, and for controlling pumps and motors. All external parts of the cartridge are zinc-nickel plated to DIN 50�979 and are thus suitable for use in the harshest operating environments. If you intend to manufacture your own cavities or are designing a line-mounting installation, please refer to the section “Related data sheets”.