Product description

Slurry valves

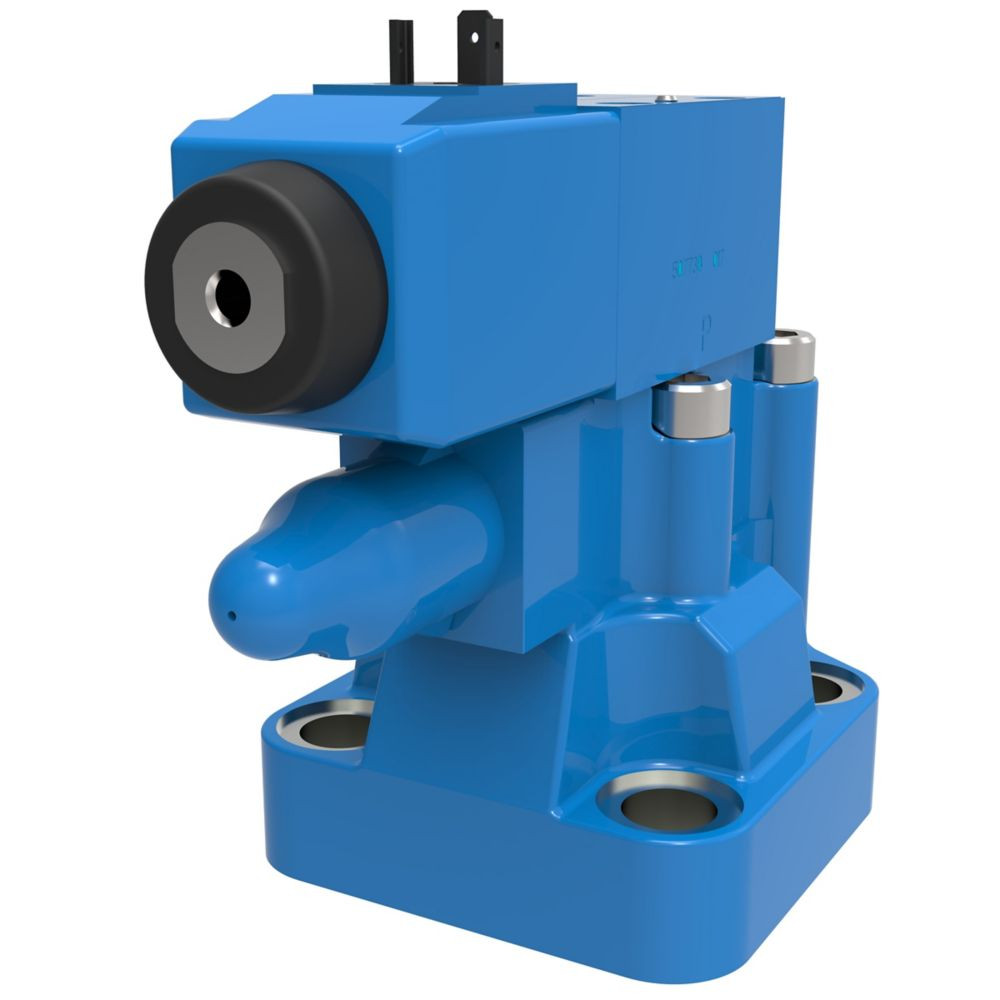

Bidirectional knife gate valve. Valve suitable for use as end-of-line.The GA valve body is a single monobloc piece. Stainless steel through-conduit gate. Two rubber sleeves. The main characteristic of this slurry valves is that it provides a full continuous flow. This means that in open position it produces no cavities and there is no turbulence in the fluid. The stem protection hood is independent from the handwheel securing nut, this means the hood can be disassembled without the need to release the handwheel. This advantage allows regular maintenance operations to be carried out, such as lubricating the stem, etc. The CMO valve stem is made from stainless steel 18/8. This is another additional benefit, since some manufacturers supply it with 13% chrome, which quickly rusts. The operating wheel is manufactured in nodular cast GJS-500. Some manufacturers supply it in common cast-iron, which can lead to breakage in the event of very high operation torque or a bang.

Utilization

Thats knife gate slurry valves are suitable for working in the mining industry, in loaded fluid transport lines such as water with stones, sludge, etc, and, in general, for abrasive fluids in the chemical industry and waste water.

Designed for the following applications:

Slurry valves for Mining, Sewage treatment, Electrical power stations

Chemical plants, Energy sector, Thermal power stations

Sizes

DN50 a DN1500

Larger sizes to order.

Working pressures

DN50 a DN600 10 bar

DN700 a DN1400 6 bar

DN1500 2 bar

The pressures indicated in the table can be used in either of the valve’s two directions.

Directives

• Pressure Equipment Directive:

(PED) ART 4.3 /CAT.1.

• Potential Explosive Atmospheres Directive:

(ATEX) CAT.3 ZONA 2 y 22 GD.